Why choose BRIQUETTING SOLUTION APAC ?

Fast return on investment

Customized solutions secure the return on investment

State of the art equipment

In house manufacturing in Germany and Denmark

Customer service

Service back up on site and remote via internet

Customer satisfaction

We strive for customer satisfaction all the way

Highlighted products

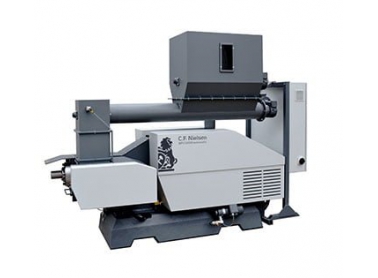

Briquetting presses

Briquetting press for wood, biomass and other material, suitable for making industrial briquettes. Briquette diameter 50 mm Capacity from 150 to 350 kg/hour depending on raw material and density requirements

Read moreBriquetting press for wood, biomass and other material, suitable for making industrial briquettes. Briquette diameter : 60 mm Capacity from 400 to 600 kg/hour depending on raw material and density requirements

Read moreBriquetting press for wood, biomass and other material, suitable for making consumer and industrial briquettes. Briquette diameter 60 mm Capacity from 500 to 750 kg/hour depending on raw material and density requirements

Read moreBriquetting press for wood, biomass and other material, suitable for making consumer and industrial briquettes. Briquette diameter 75 mm Capacity from 800 to 1200 kg/hour depending on raw material and density requirements

Read moreBriquetting press for wood, biomass and other material, suitable for making consumer and industrial briquettes. Briquette diameter 75 mm or square 65x65 mm Capacity from 900 to 1400 kg/hour depending on raw material and density requirements

Read moreBriquetting press for wood, biomass and other material, suitable for making consumer and industrial briquettes. Briquette diameter 90 mm, 100 mm, Square 75x75 mm Capacity from 1100 to 2300 kg/hour depending on raw material and density requirements

Read moreBriquetting press for wood, biomass and other material, suitable for making consumer and industrial briquettes. Briquette diameter 90 mm, 100 mm, Square 75x75 mm and 85x85 mm Capacity from 1300 to 2500 kg/hour depending on raw material and density requirements

Read moreBriquetting press for wood, biomass and other material, suitable for making consumer and industrial briquettes. Briquette diameter 100 mm,, 110 mm, 120 mm, Square 100x100 mm. Capacity from 2000 to 3000 kg/hour depending on raw material and density requirements.

Read moreOur mechanical briquetting presses from the BP2010 to the BP6510HD can be supplied as units. The Units are the same basic briquetting press, but equipped with a small dosing silo and dosing screw on top of the press. The units are supplied pre-wired for fast and easy installation.

Read moreThe BPE Shimada Extruder Briquetting Press is equipped with an advanced control system that allows internet access. It is possible to monitor, operate or search for failures and even to reprogram the PLC-function via an internet connection. All operation texts and failure notices can be shown in up to 16 languages. The log function is an important tool for analyzing and improving the briquetting process. Relay based control panel can be delivered as an alternative. The BPE Shimada Extruder Briquetting Press is sold for medium sized professional users and most types of wood and agricultural based raw materials can be used without adding a binder. The briquettes are typically used as consumer briquettes/logs for fireplaces and wood burning stoves. The briquettes are normally produced in a size of 65×65 mm with a length of 200 mm. Other sizes are optional.

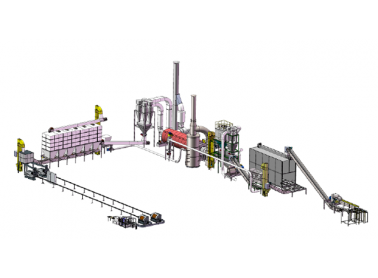

Read moreCFN ENGINEERING We are often asked to provide our expertise in regards to the design of complete production plants. As a result we are now able to offer the concept CFN Engineering. The concept includes complete briquetting solutions for wood and agricultural based raw materials. It includes everything from chipping, grinding, drying, handling to briquetting and packaging. We cooperate with different partners and the concept is only offered in selected markets.

Read moreGenerate more revenue from Briquettes The RUF briquetting presses have been sold all over the world, which has led RUF to be the generic name for the rectangular briquettes. The briquette consumers know that a RUF marked briquette ensure them a high quality of fuel, with similar characteristics and burning efficiency. The RUF Lignum series have capacities from 410 and 1,050 kg per hour.

Read moreBRIQUETTING PRESS FOR BIOGENIC RESIDUAL MATTER The RUF briquette press for biomass forms briquettes from biogenic residual matter of all kinds, including wood chips, MDF, chipboard panel residues, agricultural substances, paper and textile dust, producing briquettes of a consistently high quality and density. Our briquette press range for biomass offers maximum flexibility. The systems can be equipped with a large number of options to meet specific customer requirements. Thanks to its compact construction, the briquette press can easily be integrated into existing production processes and can be operated fully automatically, 24 hours a day.

Read moreMETAL CHIP BRIQUETTING MACHINES FOR A WIDE RANGE OF METALS & ALLOYS The value of metal residues can be greatly increased with our metal press machine. The metal chip briquetting machine is a real all-rounder and is suitable for pressing aluminium, steel, cast iron, copper and countless other metals. On the basis of the particular experience we have gained in the field of metal chip recycling, we are able to offer briquetting solutions which are individually tailored to customer-specific requirements.

Read moreBriquettes made from solid hardwood or solid softwood are often the preferred both with regards to consumer briquettes and briquettes for industrial boilers. The solid wood for briquetting is typically coming from waste (bi-product), from sawmills, wood processing factories or from branches, off-cuts etc. from the forest.

Read moreDemolition wood is the term for old pallets and of course for wood coming from demolition.

Read moreManufacturing or processing MDF, creates a lot of dust, which both can be bad for the health and also creates a dust exposion risk at the factory. With a briquetting solution the two negatives are eliminated and becomes a positive. The MDF dust as a solid briquette, can be burned in industrial boilers for energy generation. The compaction makes the costs for transportation and/or storage significantly lower.

Read moreALUMINIUM PRESSES FOR DIFFERENT THROUGHPUTS The briquetting of aluminium chips with the RUF aluminium press creates briquettes that can then be sold at a profit. As long as 35 years ago, RUF specialised in developing hydraulic briquetting presses and now develops tailor-made briquetting solutions in accordance with specific customer requirements, above all in the field of aluminium recycling. Our briquetting press for metal chips can be directly incorporated into existing production processes and is designed for fully automatic 24-hour operation.

Read more

Solutions

Customized solutions

Call

Call SMS

SMS Direct

Direct